Is There A Hole In Your Thinking?

I learned long ago that I am a visual learner. In pre-Covid days, when I had an office, it was rare for more than five minutes to pass in a conversation with a colleague before I was up at the white board, trying to see what we were saying. My friend Michael once told me that “to see what you say helps you to understand what you know rather more deeply.” More on him in a moment.

As an industrial engineer, I am process oriented. That means, amongst other things, I can help literally any organization thrive. Unlike other engineering disciplines, industrial engineers don’t need to be experts at what an organization does, we specialize in understanding and analyzing how it is done. My current organization provides 3D printing capabilities to the dental industry. Although I have several 3D printers and teeth, neither one of those facts helped me last week.

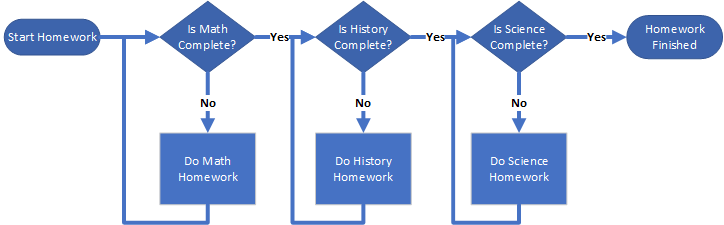

I was on a conference call with a member of our sales team and one of our external clients. We were having a conversation about the client’s work flow in order to align on requirements and make sure we are engineering a solution that most effectively meets the client’s needs. I listened for a few minutes before realizing I was getting lost. I opened up Visio and started visually mapping out what I was hearing. For 15 minutes I said nothing, quickly building a visualization of what I heard, which it turns out was two people talking past one another. It wasn’t occurring in a mean way. It was more like when I ask my daughter if she has finished her homework and she answers, “yes.” What I really want to know is if she finished all of her homework. What she answers is that she finished some of her homework.

After 15 minutes of back and forth on this conference call, my sales colleague and our client were satisfied they had defined everything and asked if I had any questions. Rather than waste time describing what I heard, I shared my screen and started asking if I had placed the various boxes and arrows correctly. As I suspected, I got it wrong—there were holes in the communication!

Process Flow Chart For Completing Homework

It’s a simple concept, drawing something to make it clearer. Industrial engineers call this process mapping, but why does it work? That is a question my former colleague, the aforementioned Michael Erickson, has thought a lot about. Michael is a self-proclaimed “envisioneer.” His job for the past 30 years is to sit with technical people and let them data dump. While they are talking, he draws a picture of what he hears them saying. He shows them the picture and they tell him it’s wrong. They discover holes in their thinking that were not captured by verbal communication. Sound familiar?

On my call last week, everyone was speaking English. Everyone understood the technical details being discussed and yet, there were holes. That’s because, as Michael once explained to me, technical dialects are often not exactly the same. Even amongst people speaking the same language with similar backgrounds, there is a very small percentage of the language that’s different, and that’s the part that fouls everything up. It’s the difference between “all” of your homework and “some” of your homework. In my conversation last week, it was the difference between “always” and “sometimes.” Imagine if my company engineered a solution on the assumption that something “always” happens, when in reality there are variations that occur up to 50% of the time!

As an envisioneer, Michael helped me understand that communication is the end of a process, not the beginning. His pictures, like my process map, synthesize information in order to achieve coherence. Only then can real communication occur. Technical people are like musicians with instruments, they come together with information that represents a facet of a bigger idea. Between those facets are holes that prevent coherence. Just as a band leader pushes music notes around into a coherent piece of music, a person like Michael uses art to push ideas around and synthesize them. Drawings help synthesize the facets of verbal stories—they hold the space in the conversation until coherence is reached. This is the core of systems thinking, being able to integrate pieces of things and understand how those pieces relate to one another. Without coherence and systems thinking, you just have a lot of noise, and noise is what a lot of organizations solve for.

Last week, I used a process map to help my team see what they were saying and thus understand what they know more deeply. It cut down on the noise and helped us focus on the real problems to be solved. We found the holes in our thinking. Does your organization solve for noise or fill in the holes to reveal the real problem? Perhaps you can be the hole finder on your team. Go to the white board, load up Visio, or just take a picture of a napkin sketch. You’ll be amazed at where communication really begins.